Analysis and Design of Final Clarifiers

The Budds Farm Sewage Treatment Works (STW) operated by Southern Water treats waste water from the Portsmouth and Havant catchments. Prior to 2006, the STW at Budds Farm had 8 final clarifiers of 35m internal diameter. In order to meet the requirement of the projected AMP4 flows, the existing settlement tanks were modified and 2 new 35m diameter clarifiers have been built to operate alongside the existing 8 tanks. MMI Engineering was commissioned by 4D/Southern Water, to undertake a programme of computational modelling and hydraulic analysis for the 8 existing and 2 new clarifiers. The objective of this work was to calculate the performance of the clarifiers and to confirm the solids loading with and without internal modifications.

A verified and validated CFD modelling technique was used to determine the internal hydrodynamic performance of the final settlements tanks [fusion_builder_container hundred_percent=”yes” overflow=”visible”][fusion_builder_row][fusion_builder_column type=”1_1″ background_position=”left top” background_color=”” border_size=”” border_color=”” border_style=”solid” spacing=”yes” background_image=”” background_repeat=”no-repeat” padding=”” margin_top=”0px” margin_bottom=”0px” class=”” id=”” animation_type=”” animation_speed=”0.3″ animation_direction=”left” hide_on_mobile=”no” center_content=”no” min_height=”none”][1]. The simulations were performed in two dimensional, axi-symmetric co-ordinates with models for sludge settling, mixture density and viscosity.

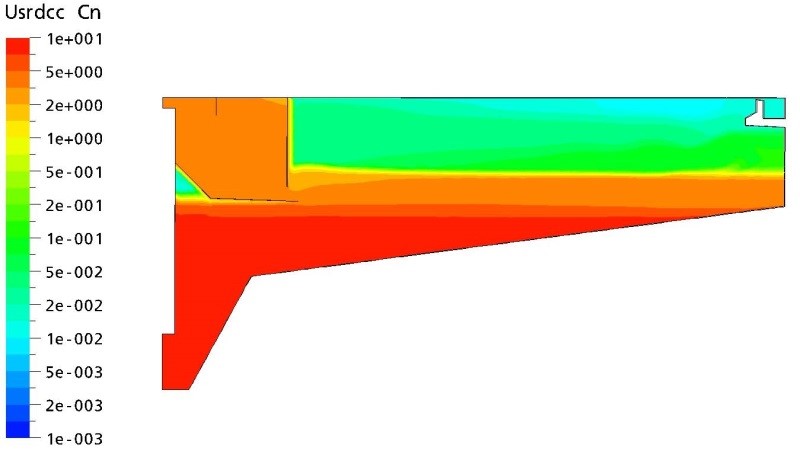

Figure 1 shows contours of solids concentration for the new tank. It was found that the existing tank with Ø7m diameter stilling well (as built) would only work up to 70% of FFT.

Figure 1: Solids Concentration in Log Scale (0 to 10 kg/m3) for the new Tank at FFT

The MMI designed McKinney baffle modification worked better at high solids loading and SSVI, enhancing the capacity and performance of the existing tanks by up to 26% in flow. The proposed new tank with Ø10m diameter stilling worked well up to 70% of FFT but the McKinney baffle influent modification enhanced the capacity and performance of the new tank by up to 20% in flow. MMI provides the capability to optimise the internal modifications prior to construction. In this case the investigation revealed that the influent design had a significant impact on the clarifier performance. A modified influent, designed by MMI, and incorporating a sloped McKinney baffle + deflection ring gave > 20% improvement in the site maximum forward flow. The recommended design of influent has been incorporated on all 10 tanks at Budds Farm (Fig 2).

Figure 2: Ø35m Tank with MMI Designed McKinney Baffle and Deflection Ring

References

- Burt, D. and Ganeshalingam, J., Design and Optimisation of Final Clarifier Performance with CFD Modelling, Presented at the CIWEM / Aqua Enviro joint conference on Design and Operation of Activated Sludge Plants, Leeds, UK, 19th April 2005.

For more information surrounding computational modelling and hydraulic analysis services, please contact us on 0117 960 2212 (Bristol) or email us.[/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]