Using CFD to Determine Thermo and Hydrodynamic Conditions Within a Spent Fuel Canister

Geological disposal is the UK’s long term approach in the management of radioactive waste and spent nuclear fuel. Canisters of nuclear fuel are placed in an underground repository, and so the integrity of the canister design(s) is key in ensuring the containment of radioactivity.

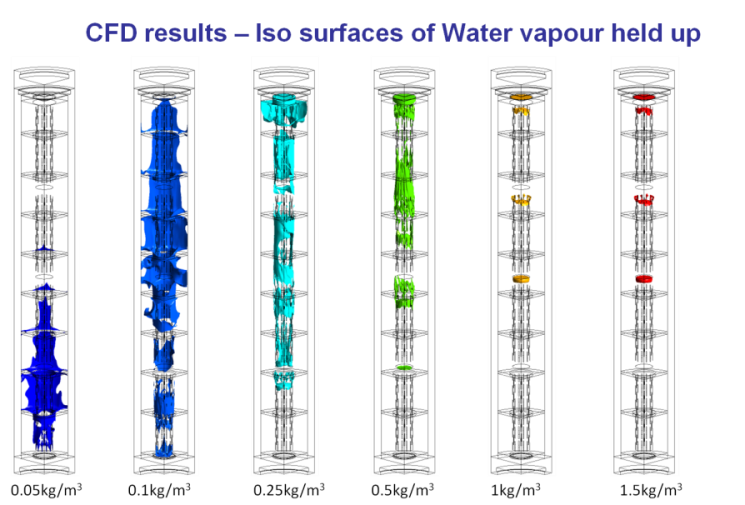

Water Carry-Over and Corrosion

MMI Engineering used CFD to determine the thermo and hydrodynamic conditions within a concept spent fuel canister for geological disposal. These assessments were used to understand the potential for canister material corrosion as a result of water carried-over at the point of canister closure whilst in above-ground storage. The model also provided information on the potential for canister pressurisation due to vaporisation caused by heat from the fuel.

Dropped Object Analysis

Dropped object analysis of an SF Disposal Canister was conducted using ABAQUS Explicit Finite Element Analysis. Two scenarios were considered, which relate to the types of drop incident that could potentially occur during pre-emplacement:

• An 8m vertical drop onto a flat unyielding target

• Impact onto a mild steel ledge mounted on a flat unyielding target after toppling freely from an upright position

Material Properties

MMI sourced and used full true stress – true strain curves for the flask materials. An elastic – perfectly plastic response based on the minimum yield stress of the steel would have given a more conservative analysis in terms of the strain during impact; however, a key consideration for this application is the residual stresses in the system.

Conclusions

The residual stresses in the system, combined with corrosion due to water carryover could have implications for the long term integrity of the canister.

For more information surrounding our CFD expertise, or to discuss your Nuclear Industry project requirements, please contact us on 0117 960 2212 (Bristol) or email us.