MMI Engineering is an established provider of engineering analysis, major accident hazard assessment and risk management services to clients in the following industry sectors:

- Oil and gas

- Petrochemical Renewable Energy

- Utilities and Infrastructure

- Nuclear

- Aerospace

- Security and Defence

- Insurance

The company ethos is to develop, adopt and apply the most appropriate scientific and engineering solutions to our customers – solutions which meet both corporate and regulatory requirements. Our services are provided by experienced and highly qualified professionals from diverse technical backgrounds, with strong focus on technical excellence and value to the customer.

As members of both the UK Hydrogen Association and the UK Carbon Capture and Storage Association (CCSA), MMI is committed to supporting the public and regulatory acceptance of Carbon Capture Storage (CCS) and hydrogen power generation by contributing to the understanding and management of associated major hazards and risks.

Where We Operate From

[fusion_builder_container hundred_percent=”yes” overflow=”visible”][fusion_builder_row][fusion_builder_column type=”1_1″ background_position=”left top” background_color=”” border_size=”” border_color=”” border_style=”solid” spacing=”yes” background_image=”” background_repeat=”no-repeat” padding=”” margin_top=”0px” margin_bottom=”0px” class=”” id=”” animation_type=”” animation_speed=”0.3″ animation_direction=”left” hide_on_mobile=”no” center_content=”no” min_height=”none”]

UK

- Warrington

- Bristol

- Aberdeen

- York

- Belfast

USA

- Houston

- San Francisco

- Los Angeles

Australia

- Melbourne

- Perth

Malaysia

- Ipoh

- Kuala Lumpur

CCS

CCS projects bring together, in a novel way, a range of established and emerging technologies. This introduces challenges for facility operators and regulatory authorities, not least of which is to identify, assess and manage health, safety and environmental risks. The capture, collection, transportation and long term storage of large volumes of CO2, especially in and around major industrial and urban centres, demands a rigorous understanding of related major accident hazards. In the case of pre-combustion carbon capture, the production and handling of large volumes of hydrogen-rich synthesis gas, with potential for associated hydrogen sulphide, also introduces significant hazards. The injection of CO2 into existing oil/gas reservoirs for Enhanced Oil Recovery (EOR) adds additional hazards to offshore installations and increased complexity of operations. Existing oil and gas experience does not directly transfer to an understanding of CO2 hazards. MMI Engineering is well placed to support facility operators and their engineering contractors in identifying, assessing and managing the process safety and major accident hazard challenges of CCS projects.

MMI has supported and continues to support a number of power generation and CCS projects in the UK, US and Middle East. This experience is summarised below:

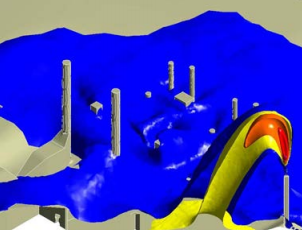

BP/SSE 500MW Peterhead Hydrogen Power

Provided extensive major hazard support to Peterhead Hydrogen Power – the first UK CCS project to obtain full planning and regulatory approval; all aspects of hazard modelling, including CO2 and hydrogen syngas related studies. MMI provided CO2 dispersion analysis modelling support (CFD), as well as explosion and fire modelling for input to the COMAH (Control of Major Accident Hazards Regulations) Pre-Construction Safety Report. In addition to this, MMI provided the HSSE Team Leader for BP, managing safety, environmental and other regulatory requirements throughout the project FEED stage.

Provided extensive major hazard support to Peterhead Hydrogen Power – the first UK CCS project to obtain full planning and regulatory approval; all aspects of hazard modelling, including CO2 and hydrogen syngas related studies. MMI provided CO2 dispersion analysis modelling support (CFD), as well as explosion and fire modelling for input to the COMAH (Control of Major Accident Hazards Regulations) Pre-Construction Safety Report. In addition to this, MMI provided the HSSE Team Leader for BP, managing safety, environmental and other regulatory requirements throughout the project FEED stage.

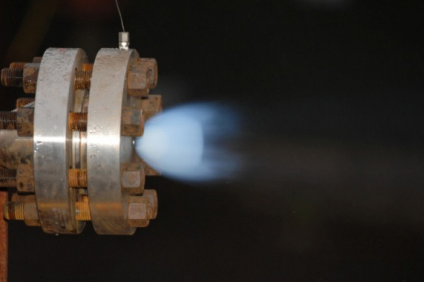

BP/SSE CO2 Experimental Release Project

MMI provided the Project Manager for this work, the first dense phase CO2 release experimental programme in the UK. In addition to this, MMI were one of four companies selected for the ‘blind modelling’ phase of this project, which went on to support validated models for dispersion analysis of CO2, a major requirement for the development of CCS projects.

Eston Grange Power Project UK 900MW IGCC

MMI staff provided project management for the development and permitting of this project, a joint venture between Centrica Energy and Progressive Energy. In addition to the overall power plant development, this included risk assessment and development of pipeline routes for both Natural Gas (start-up fuel) and CO2. CO2 routes for this project included EOR and/or saline aquifer storage, with the capacity to transport CO2 from other industrial sources.

MMI staff provided project management for the development and permitting of this project, a joint venture between Centrica Energy and Progressive Energy. In addition to the overall power plant development, this included risk assessment and development of pipeline routes for both Natural Gas (start-up fuel) and CO2. CO2 routes for this project included EOR and/or saline aquifer storage, with the capacity to transport CO2 from other industrial sources.

E.ON UK Kingsnorth 1600MW CCS Project

MMI supplied process safety engineering support to the E.ON project team for design safety input across the whole of the project, inclusive of the flow assurance (Genesis Oil and Gas), and dispersion modelling work (E.ON ENT). MMI’s consultant chaired E.ON’s operational safety working group and supported the CO2 transportation working group.

CO2PIPETRANS JIP (Joint Industry Project)

MMI has been a key supporter of this JIP, a cooperation of operators, suppliers and regulators aiming to close technical knowledge gaps relating to CCS technology. MMI has undertaken dispersion work and designed test rigs. MMI is also an active member of the follow on JIP, CO2PIPETRANS2.

Safety Support

Early safety support to a US Integrated Gasification Combined Cycle (IGCC) and CCS project (client confidential). Using our internally developed HAZID workshop management and recording tool, MMI conducted hazard identification workshops at the early stages of this project.

Assessment of CCS Technologies (Steel Manufacturing, USA)

Review of manufacturing practices at large, integrated steel mills to identify potential opportunities for economically capturing CO2, including a more detailed assessment of blast furnace off-gas.

CCS and Distributed Power Generation Tokyo Gas, Japan

Development of a “systems view” of distributed generation that allows an understanding of the technical challenges and economic trade-offs of making a system capable of capturing CO2 for disposal or utilisation. Evaluation of various components of a systems approach to distributed generation with Combined Heat and Power (CHP) and CCS.

Ohio River Valley CO2 Storage Project

Geochemistry investigation for geologic sequestration of CO2 in deep sedimentary basins for the US Department of Energy, Mountaineer Plant, New Haven, West Virginia, including the assessment of the long-term behaviour and storage of CO2 by detailed geochemical characterisation of in situ formation fluids. This work was conducted under the Ohio River Valley CO2 Storage Project, funded by U.S. Department of Energy, American Electric Power, BP, The Ohio Coal Development Office, Schlumberger, Battelle, and Pacific Northwest National Laboratory.

MMI’S Services to Power and CCS Projects

MMI can provide a range of services, from initial HAZID/HAZOP workshops, through to detailed modelling of hazard consequences, both onshore and offshore. Specific services include:

- Facility layout review, hazard identification and screening studies

- Consequence modelling of all relevant major accident hazards, including hydrogen syngas deflagration, detonation and jet fires, H2S release and dispersion, release, dispersion of sub-cooled, liquid and supercritical CO2

- Assessment and design of structures to resist applicable hazards, both explosion overpressure and missiles

- Ventilation, dispersion and explosion analysis within gas turbine enclosures, both within a PM84 context or as part of more general assessments

- Pipeline rupture release and dispersion modelling, both steady state and transient

- Quantitative risk assessment and safety case support

- CFD modelling

- Flow assurance for CO2 pipeline systems

- Fire detection system layout optimisation using

- MMI proprietary software techniques

MMI adopts a cooperative and iterative approach in delivering these services, collaborating with the client, engineering contractor, other consultants and regulators as required.

CCSA and Energy Institute

MMI currently provides the Co-Chair for the Technical Working Group of the CCSA, and a Steering Group member for the Energy Institute, which is focussed on the drafting of CCS Guidelines.[/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]