Improving the Dosing Performance of UV Treatment Equipment

UV disinfection has been used for many years to treat grey and waste waters. UV sources are increasingly being used to inactivate pathogens in drinking water – including cryptosporidium oocysts.

Although target dose rates can be specified for the inactivation of pathogens, it is difficult to design configurations of UV tubes that guarantee the target dose reaches all of the flow. This is a particular issue for larger scale systems.

MMI Engineering have worked with manufacturers of UV treatment equipment to improve dosing performance. We have developed and enhanced a modelling technique based around Computational Fluid Dynamics (CFD) that can be used to assess the dose given to a water stream and to compare systems.

Modelling the Flow

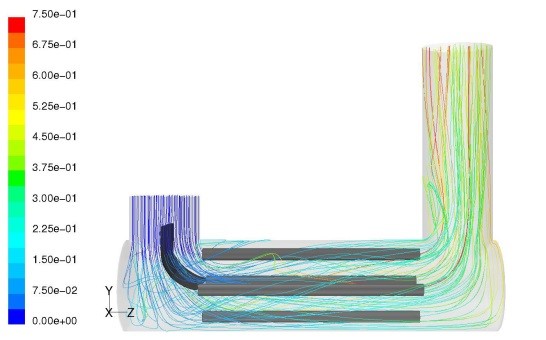

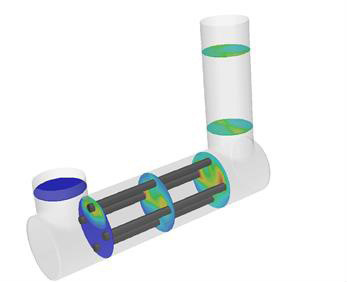

The full 3D geometry is built or imported from CAD and the flow conditions are supplied along with the fluid properties. The Navier Stokes fluid flow equations are solved to give the flow distribution and a further equation is solved to evaluate the UV radiation field distribution. Fluid stream lines are then tracked through the flow and cumulative UV radiation dose to the stream is computed.

Left: Flow distribution and particle tracks in a UV treatment system with an entry splitter plate. Right: A Contour Plot of Cumulative UV Dose on the Water. This Design has no Splitter Plate and Shows Evidence of Short Circuiting

Processing and Comparison

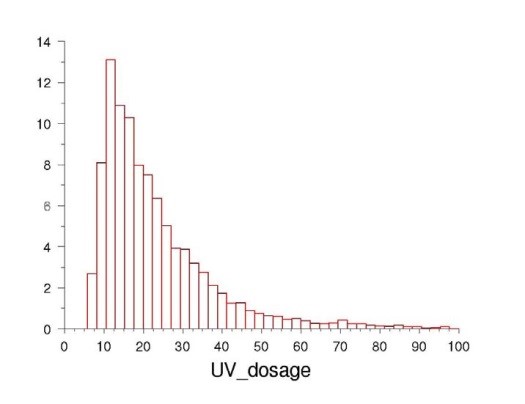

The base flow information is augmented with UV dose data to give the designer a pictorial view of problem areas. UV dosage can also be quantified in a histogram of the total flow.

UV Dosage Distribution Histogram Indicates the % of the Flow Seeing a Certain Dose Rate

This information is particularly useful for comparing design alternates. Using these tools, MMI has conducted modelling investigations for clients on flow and dose rate, including modifications to:

- Chamber geometry

- UV tube layout & power

- Upstream & downstream geometry

- Inflowing water properties

For more information surrounding our flow capabilities in the Water Industry, please contact us on 0117 960 2212 (Bristol) or email us.