Modelling Service Reservoirs and Contact Tanks

The design of a good contact tank depends on its ability to promote plug flow, which will provide water of uniform treatment quality to a domestic water supply. CFD techniques can be used to generate detailed information about flows, Residence Time Distribution (RTD) and chlorine degradation in water treatment systems.

Modelling the Flow and RTD

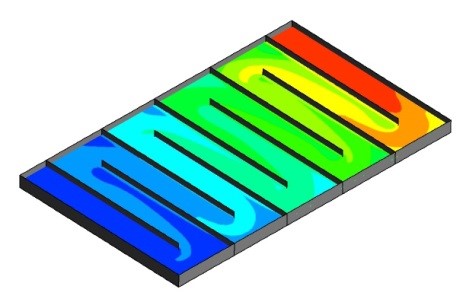

The basic hydrodynamics are generated from a three dimensional model of the geometry, with boundary conditions applied to represent inflows, outflows and the presence of free surfaces. A simple age scalar can be used to show recirculation and emphasise the quiescent flow regions.

Figure 1: A Rectangular Service Reservoir with Baffles Explicitly Modelled. An Age Scalar is Used to Show the Youngest Water Jetting in (blue) and the Oldest Water Gathering (red) in the slower moving regions

CFD predictions for RTD can be compared with field experiments using dye tracers. In an experiment, a number of conductivity probes were placed into a tank and a slug of sodium fluoride was introduced at the inlet. The conductivity probes picked up the signature of conductivity against time, indicating the path of the salt through the system. This same experiment can be performed within the CFD model.

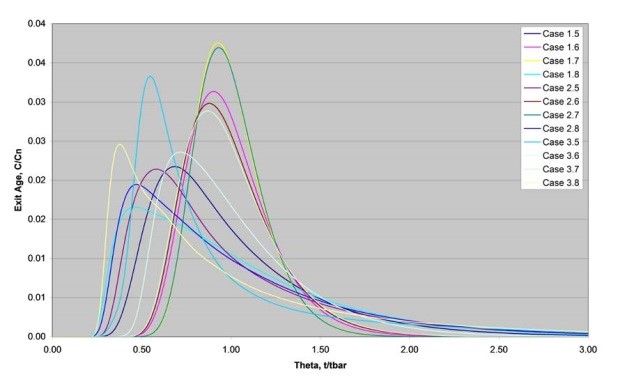

Figure 2: Graph of Exit age Distribution in the Reservoir Normalised Against Hydraulic Retention Time

Modelling Chemical Reactions

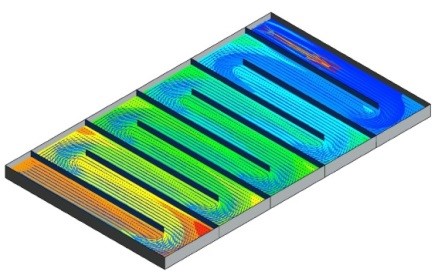

Chemical species can be added to the flow model to represent the passage of Chlorine re-circulating, decaying and being consumed in the reservoir.

Figure 3: Chlorine Concentration. Note how the Oldest Water (see Figure 1) Corresponds with the Region of Lowest Chlorine

Conclusions

This analysis provides useful information to contact tank designers. Regions of old water with low Chlorine concentration are clearly identifiable, meaning that necessary modifications can be made. For example, access covers, which can provide access to contaminants, can be located away from such regions. Key design parameters, such as t10 and t90, can be extracted from the RTD curve and used to calculate the tank efficiency and the number of tanks in series.

For more information surrounding our flow capabilities in the Water Industry, please contact us on 0117 960 2212 (Bristol) or email us.