Primary Settlement Tank Design

The purpose of a Primary Settlement Tank (PST) is to remove Biochemical Oxygen Demand – BOD (solids), therefore reducing the load on the secondary treatment and final effluent. The sludge produced can then be used for agricultural purposes or biogas generation. PST’s do not have a Fats Oil and Gas (FOG)/scum separation purpose, but inevitably some comes to the surface, and so most PST’s have scum removal. At one particular site, it was found that within the stilling well, the layer of FOG was 12 to 18” thick.

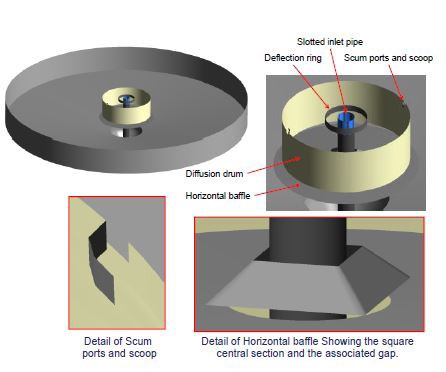

Figure 1 presents the key features of the tank, which include the stilling well, a deflector ring and scum ports. While the presence of the FOG was not detrimental to the performance of the primary tanks, when the tanks were drained down for maintenance, the FOG would collect on a horizontal inlet baffle, causing the baffle to deform.

Figure 1: Primary Settlement Tank

MMI was asked to undertake a programme of Computational Fluid Dynamics (CFD), so that alterations to the design of the stilling well could be analysed. MMI considered alterations to the scum ports, the scoops and deflector ring.

Modelling the Flow

The basic hydrodynamics were generated from a model of the geometry, with boundary conditions applied to represent inflow and outflow. The FOG is a suspension of particulates, which coalesce to form a solid material at the surface.

MMI’s expertise in multiphase flow was used to select appropriate models to represent the behaviour of the FOG.

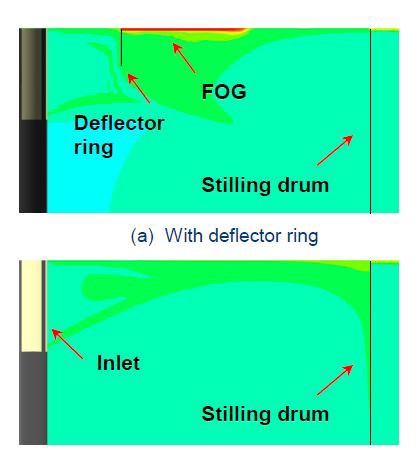

Figure 2: Distribution of FOG with and without the deflector ring

Results

It was found that solids accumulated between the ring and the stilling drum of the deflector ring. In the absence of the ring, the momentum of the inlet flow distributed the FOG, and was found to minimise accumulation of FOG within the stilling well

Value Added

Ad-hoc changes to the stilling well would have been difficult to implement, because in order to do this, the tank would have had to be taken out of service. Therefore, CFD was used to determine the optimum design change before alterations to the stilling well were actually implemented.

For more information surrounding our Multiphase Flow capabilities in the Water Industry, please contact us on 0117 960 2212 (Bristol) or email us.