Re-Suspension of Aeration Lanes

Severn Trent Water commissioned MMI Engineering to investigate the optimal configuration of the Aqua Turbo® aerators at the Melton Mowbray Sewage Treatment Works. These units aerated the mixed liquors using a screw impeller that drew up and impinged the fluid onto a flat plate above the water surface, creating a spray (as shown in Figure 1).

Figure 1: Aqua Turbo® Aerator

Attached to each unit was a draft tube that protruded into the aeration lane with the aim of inducing re-suspension and promoting the mixing of the sludge. Although the mixing energy density applied to the system should have been sufficient to hold the mixed liquors in constant suspension, the experimental evidence suggested that substantive regions of the tank remained unmixed. Therefore, MMI investigated three draft tubes of different lengths to determine which was the most effective at transferring the mixing energy into the solids suspension.

A transient Computational Fluid Dynamic (CFD) process model of the Aqua Turbo® Aerators was developed and the sludge phase was modelled using drift flux theory with the slip velocity, or hindered settling, modelled according to Tákacs [fusion_builder_container hundred_percent=”yes” overflow=”visible”][fusion_builder_row][fusion_builder_column type=”1_1″ background_position=”left top” background_color=”” border_size=”” border_color=”” border_style=”solid” spacing=”yes” background_image=”” background_repeat=”no-repeat” padding=”” margin_top=”0px” margin_bottom=”0px” class=”” id=”” animation_type=”” animation_speed=”0.3″ animation_direction=”left” hide_on_mobile=”no” center_content=”no” min_height=”none”][1]. Given the SSVI of the activated sludge, the free settling velocity and free settling parameter in the Tákacs model were obtained from the Pitman [2] and White [3] correlations. The rheology of the fluidsolids mixture was modelled according to Bokil and Bewtra [4].

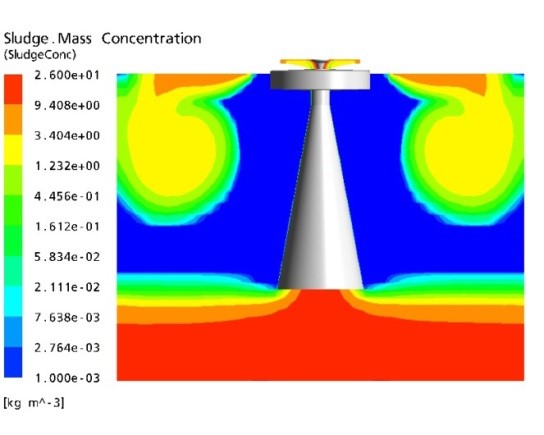

It was found that the most effective draft tube for suspending the settled bed and maintaining the solids in suspension was the longest one. It was also observed that the longest draft tube was able to suspend a settled bed faster than the other draft tubes investigated. Figure 2 shows the longest cone at the onset of re-suspension.

Figure 2: The Longest Cone Draft Tube Suspending Solids from a Settled Bed. Concentration is shown in log scale 1 to 2600 mg/l

MMI enabled Severn Trent Water to assess the adequacy of draft tube designs prior to construction. In this case, the client used the CFD results to justify the modification of the plant with the longer draft tube. This meant that the cost over-run associated with installing a shorter draft tube was prevented.

References

1. Tákacs, I., Patry, G.G., Nolasco, D., 1991, A Dynamic model of the clarification-thickening process, Water Res., 25(10), pp. 1263-1271

2. Pitman, A.R., 1980, Settling Properties of Extended Aeration Sludge, J. Wat. Pollut. Control Fed. 52(3), 524- 536

3. White, M.J.D., 1975, Settling of Activated Sludge, Technical Report TR11, Water Research Centre, Stevenage, UK

4. Bokil, S.D., Bewtra, J.K., 1972, Influence of mechanical blending on aerobic digestion of waste activated sludge, Proc. 6th Int. Assoc. on Water Pollution Research and Control, London, pp. 421-438

For more information surrounding our risk assessment capabilities in the Water Industry, please contact us on 0117 960 2212 (Bristol) or email us.[/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]