Reviewing WTW Disinfection Process to Meet Regulations

Upton Scudamore Water Treatment Works (WTW) is a groundwater treatment works located near Warminster in Wiltshire. The works has a maximum daily output of 15Ml/d, and the water can supply over 100,000 customers in the surrounding area. Upton Scudamore WTW is supplied with raw water from three distinct sources; two from ground water springs (9 Ml/d total) and another from boreholes (6 Ml/d). Tailored treatment processes are required for the springs (chlorine disinfection only) and boreholes (iron oxidation, then filtration and chlorine disinfection).

In order to eliminate the risk of cryptosporidium contamination and to meet the reworded requirements of the DWI Water Supply (Water Quality) Regulations, Wessex Water included a review of the disinfection process as part of the AMP5 capital maintenance scheme to introduce ultra-violet treatment at this site.

The existing site combined all three sources of water in a single contact tank, which also acted as a balancing tank for pumping the water up to the service reservoir for supply. In order to ensure the site met the disinfection policy, a dedicated contact tank was required for the spring water. This was achieved by converting the 5-lane contact/balancing tank to a 3-lane contact tank with balancing tank. MMI Engineering was commissioned by Grontmij UK (on behalf of Wessex Water) to undertake a programme of Computational Fluid Dynamics (CFD) modelling and analysis on the dedicated contact tank.

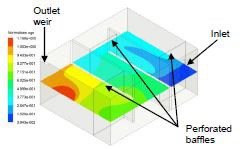

Figure 1: Optimised Model of CFD Tank Showing Water Age

Verified and validated 3-dimensional CFD modelling techniques were used to determine the flow patterns and water age through a dye-trace simulation. This established the residence time distribution and the hydraulic efficiency. Initial analysis identified short circuiting, due to flow accelerating around the lane ends, and regions of recirculation. An unacceptably low efficiency of 43% was predicted. Due to the structural design of the tank, it was not possible to modify the existing baffle walls. Therefore, additional perforated baffles were introduced near the start of each lane to reduce short circuiting. Figure 1 shows contours of water age predicted by the CFD analysis. The three additional 50% open-area baffles improved the hydraulic efficiency of the tank to 69%. This satisfied the minimum contact time and ensured acceptable chlorination of the spring water.

Results

MMI assessed the adequacy of the proposed equipment and pipe modifications prior to any onsite changes. In this case, surge analysis was used to determine the unsuppressed system behaviour and to optimise the required surge equipment to ensure safe operation. The recommended equipment was a 5m3 vessel upstream, a 2m3 vessel downstream, and a pump flywheel with an inertia of 80 kg m2.

Figure 2: Perforated Baffle plate with integral door. Picture courtesy of Wessex Water.

Value Added

MMI is capable of optimising existing structures through internal modifications to maximise chlorine contact performance. In this case, the investigation revealed that the inclusion of three 50% open-area baffle plates (Figure 2) would reduce short circuiting and increase hydraulic efficiency by more than 35% – ensuring that the minimum contact time and hence appropriate water treatment was achieved.

For more information surrounding our CFD and Surge Analysis capabilities in the Water Industry, please contact us on 0117 960 2212 (Bristol) or email us.