Ribble Link Surge Analysis

A study was conducted to assess the introduction of two temporary pump-sets on the Ribble Link pipeline, connecting a Service Reservoir (SR) to the Haweswater Aqueduct (HA). The Ribble Link main currently transfers water under gravity from the SR, but the temporary pumps will be operated intermittently to enhance the gravity flow at more than twice this rate. This will condition the main for higher flow rates. However, pumping will be intermittent due to the limited capacity of the SR, and refilling of the SR is likely to occur on a daily basis by pumping water from the Hodder Aqueduct using a transfer pumping station.

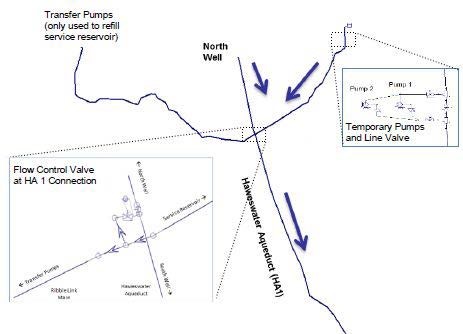

The surge analysis required the adaptation and simplification of a Flowmaster model (Figure 1) that had previously been created from a semi-automated conversion of a SynerGEE water distribution model. The model was updated with the inclusion of the new pumping and line valve equipment near the service reservoir, and a flow control valve at the connection to the HA.

Figure 1: Flowmaster Network Model with Detail Inserts Showing Temporary Pump-Sets and Line Valve Near the Service Reservoir and Flow Control Valve at the HA Connection

This model enabled the surge events associated with the new equipment to be assessed for undesirable conditions. In particular, the study focused on establishing the system pressures for pump trip, controlled stop and pump start-up operations, as well as considering the inadvertent closure of the line valve during the service reservoir refilling operation.

The aim was to ensure that the maximum pressure did not exceed the pipeline rating (potential pipe failures) or fall below atmospheric pressure (potential ground water ingress). Results in the form of envelopes for each main were presented for the complete system, identifying the maximum and minimum heads. Analysis identified that the system would not be subjected to undesirable surge pressures due to pump trip, stop or start events – even without the surge vessel in operation at the transfer pumping station. However, analysis of the inadvertent closure of the line valve during refilling identified that significant overpressures would be created.

Limiting the rate of valve closure and installing a pressure relief valve to relieve pressure from upstream (HA side) of the line valve to downstream (SR side) reduced the peak heads to acceptable values. The flow capacity and pressure setting of the relief valve was optimised to maximize performance while preventing inadvertent opening during operation of the temporary pumps.

For more information surrounding our Surge Analysis services in the Water Industry, please contact us on 0117 960 2212 (Bristol) or email us.