Analysing Operational Loading Conditions of Critical Components

When nuclear fuel overheats, zirconium cladding used in the fuel rods oxidises and produces hydrogen, which is highly flammable when mixed with air. A way to manage such a hydrogen build up is to fill the reaction chamber with an inert gas – generally nitrogen. MMI were asked to support the design of a new nitrogen deluge system, which would be installed at a number of sites within the UK.

Liquid Nitrogen Vessels

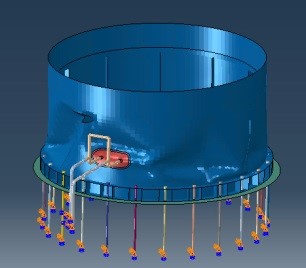

The nitrogen deluge system converted stored liquid nitrogen to gaseous nitrogen and then delivered it to the reactor. In order to ensure the suitability of the design, every aspect had to be checked and analysed for all site loading conditions. The liquid nitrogen was stored in tall vessels, which were assessed for the potential to fail under both wind and seismic loading. Critical checks were made on local buckling of the tank skin and the anchorage into the base slab.

Figure 1: Potential Buckling Failure of LN Tank Failure Base from Finite Element Analysis (FEA)

Pipework & Vaporisers

In order to transport the nitrogen from the vessels to the reactor, a number of pipeline systems were required. The pipework itself would experience significant loading due to the temperature variation caused by the liquid nitrogen. A number of recommendations were made in order to reduce localised stresses and produce a more efficient design. The liquid nitrogen was converted to gaseous nitrogen by vaporisers. These included a series of extruded aluminium fins, which improved the efficiency of the system. During the heat transfer, ice build up occured on the vaporiser structures, which influenced the seismic response.

Local Control Room

A single storey Local Control Room (LCR), housing the instrumentation and monitoring systems for the facility, was also considered. The structure was analysed using numerical modelling, paying close attention to the anchorage loads. In addition, the internal systems were qualified by shake table testing, which considered the potential for in-structure amplification from the floor of the LCR.

Conclusions

MMI considered all operational loading conditions, including wind, thermal, and seismic assessments of criticial components. Results from these analyses were used to fully qualify the nitrogen deluge system prior to installation and operation.

For more information surrounding our Structural Engineering abilities, or to discuss your project requirements, please contact us on 01925 230 655 (Warrington) / 0282 5632 916 (Northern Ireland) or email us.