Chlorine Contact Tank Optimisation and Surge Vessel Replacement

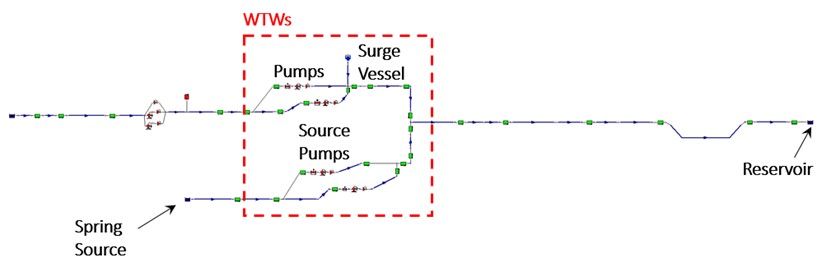

A Water Treatment Works (WTW) was being upgraded. Specifically, the WTW’s chlorine contact tank was being optimised, and its surge vessel was being replaced. The basis for the sizing and location of the existing surge vessel was unknown. The vessel was there to protect the system from pressure surges that could occur due to power failure (and hence pump trip). The works was located in an area that needed to guard against cryptosporidium, and failure of the pipes could potentially result in ingress of groundwater, particularly if a pump trip was to result in sub-atmospheric pressure at vulnerable locations in the pipe network.

Figure 1: Schematic of Pipe Network

MMI was contracted to assess the hydraulic performance of the contact tank and the network, and to identify equipment and control methods that would prevent pressures exceeding the minimum and maximum rated value of the pipework.

Our Approach

Our analysis of the system found that a single vessel would not provide adequate protection, and that a second surge vessel was necessary. Despite this, both vessels would be significantly smaller than the existing vessel, therefore providing better protection of the works without any significant increase in the volume of the equipment. We also discovered that orifice plates and non-return valves, positioned appropriately on the two surge vessels, would provide further benefit with respect to protecting against any pressure surges. Additionally, due to the head of water between the WTWs and the reservoir, we advised that fast-acting non-return valves would provide better protection from low pressures should a pump trip occur. We assessed the design of the contact tank and suggested improvements to the inlet and outlet arrangement using a spreadsheet method to estimate the best performance. This estimate was subsequently confirmed by a Computational Fluid Dynamics (CFD) calculation.

Figure 2: Contours of Water Velocity at the Free Surface

Conclusion

With regards protecting against pressure surges, we were able to not only advise on the optimium size of the surge vessel – we were also able to recommend the best solution that would provide the most protection to the WTWs. Furthermore, we were able to substantiate our findings, including the optimal arrangement of the chlorine tank, using hand calculations, 1D network assessments and CFD. The above demonstrates how MMI’s diverse mix of specialist services can contribute to supporting the upgrade of WTWs.

For more information surrounding our Fluid Mechanics abilities, or to discuss your project requirements, please contact us on 0117 960 2212 (Bristol) / 01904 428 721 (York) or email us.